Excellent performance in the high current test: TOV reached 1.25Ur and 1s was higher than the standard 1.2Ur and 0.1s.

Higher protection level: TOV reached 1.25Ur and 1s was higher than the standard 1.2Ur and 0.1s.

High performance in 8/20µs charge test: Ures change is within 3% and Ures change is within 1% after Qrs 0.4C charge test with 8/20µs waveshape for TGE D36.

High performance in short circuit test: TGE wound core for customer passed 16kA short circuit test.

Stable aging performance.

High energy absorption capability.

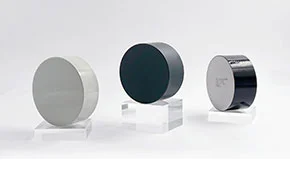

First of all, the stability of the electrical parameters of metal oxide varistor mov under continuous operating voltage.

The artificial accelerated aging test proves that in the life cycle of the MOV, its power consumption shows a declining trend with time. This means that in the long-term operation of the MOV or arrester, the power consumption or heat generated by itself will not gradually increase, so the MOV or arrester is in a stable state. On the other hand, when the MOV or arrester is subjected to continuous operating voltage for a long time, the influence of the change in ambient temperature on the power consumption or resistive current of the MOV is also a factor that affects the operational stability of the MOV or arrester. Since the power consumption or resistive current of the MOV has a positive temperature coefficient, anyway, as the temperature increases, the power consumption or resistive current will show an increasing trend. But in spite of this, the improvement of manufacturing technology can make the change of power consumption or resistive current with temperature as small as possible, which is conducive to the safe operation of the arrester. The figure shows that the aging characteristics of the D36& D42 series MOVs show that the power consumption increases monotonously as the application increases. The figure shows the change in power consumption of the MOV at different temperatures. Especially at a temperature of 190 ° C, the power consumption of the MOV sheet remains low. This is particularly important for the design of lightning arresters. When operating load or TOV test, the temperature rise of the MOV is very high due to the large energy absorbed by the MOV, and only when the high temperature power consumption remains low, it is

Specification of special metal oxide varistor for heavy duty distribution arrester easier to reach the heat under the recovery voltage or MCOV voltage stable. After the surge arrester in operation absorbs overvoltage energy, due to the lower high-temperature power consumption of the MOV, the heat generation of the surge arrester is lower, which is more conducive to the safe operation of the surge arrester

Secondly, the stability of the electrical parameters of the MOV sheet after being subjected to different pulse currents. The most obvious characteristic of the mov blocks after undergoing a large pulse current and absorbing the corresponding energy is that the temperature rise and the reference voltage leakage current or power consumption and residual voltage after cooling have a certain amplitude change from the value before the pulse current. Contact metal oxide varistor manufacturer TGE for more product details.

Welcome to TGE's Customer Connect Center. Experienced specialists are here for you 365 days a year.

No.1616 TianZhang Avenue, Feng Dong Xin Cheng, Xi'an, China.